Timber floor underlay

Underlay is required any time you install an engineered timber floor or a laminate floor. These floor types are installed using a 'floating' method as they are not actually attached to the sub-floor, instead the floor boards are attached together. The underlay gets laid down over the sub-floor and the laminate or engineered floor is installed on top of the underlay. The floor boards are attached together either by gluing the tongue and groove, or by locking the boards together, if it is a 'Uniclic' or 'LOC' up system which does not require a glue.

The function of the underlay is to absorb some of the minor imperfections in the sub-floor and to slightly soften the feel when you walk on the floor. The underlay also helps to reduce reflected foot noise when walking on the floor since the flooring is not attached to the sub-floor.

When choosing an underlay for your flooring project, you must use a product that is approved by the manufacturer of the particular flooring. Also it is important to check with Strata management, if you live in a unit or apartment, what type of acoustic underlay will be required.

We can supply the following types of underlay for floating floors:

Quick-Step Combi-Lay Standard

This is a good medium-density polyolefin underlay which can be used for all floating floors. It comes with a continuous clear moisture barrier, 100 mm overlap and integrated peel and stick. The inclusion of a continuous damp proof is a requirement under most floating floor installations. With Combi-Lay, the need for additional damp proof layers is almost always avoided, making installations quicker and more cost effective.

Quick-Step Combi-Lay combines the right balance of compression, slip and damp proof characteristics into one affordable package. The 50 square metre rolls are easy to handle, while the no fuss lay flat polymers make installation simple.

Advantages

- Easy to handle: 2 mm thick x 1 m wide

- Continuous damp proofing in one application

- Lay flat polymers for easy installation

- Compatible with standard trims

- Will not hold water and will not mildew

- Low cost

- The site specific test result is L'n,w + C

1 = 44 which complies with Building Code of Australia (BCA) multi-story requirements. Test report available on request

Specification:

- Thickness supplied: 2 mm

- Water vapour transmission rate: 4.62 g/m2, 24 hours

- Water absorption: 0.07 mg/cm2

- Compression strength at 25% compression: 30 kPa

Prices:

Quick-Step Combi-Lay Standard - 20 m2 roll (20 m x 1 m x 2 mm) : $3.85 + GST per m2 or $77.00 + GST per roll.

Quick-Step Combi-Lay Standard - 50 m2 roll (50 m x 1 m x 2 mm): $3.08 + GST per m2 or $154.00 + GST per roll.

Underlay purchases are full rolls only.

This is a superior underlay where reduced foot noise and sound reduction in multi-story buildings are required. It is made of high-density polyolefin copolymer resin which effectively reduces the hollow feel when walking on floating floors. Independent University tests show at least 30% reduction in foot noise for the user, while the underlay has achieved rating of L'n,w + C

1 = 45 rating according BCA multi-story requirements. With the integrated moisture barrier there is no need for additional damp proof layers in most instances.

Advantages:

- Easy to handle

- Lay flat polymers for easy installation

- Super tough tear resistance to tools and boots

- Continuous damp proofing in one application

- Integrated peel and stick strip

- Will not hold water and will not mildew

- Super tough tear resistance to tools and boots

- Compatible with standard trims

- L'n,w + C1 = 45 (a site specific test result and complies with BCA multi-story requirements). Test report available on request.

Specification:

- Thickness supplied ISO 1923: 2 mm

- Reflected foot noise reduction: 30%

- Field impact isolation class ISO 717/2: 64

- Water vapour transmission rate ASTM E96: 1.7 g/m

2, 24 hours

- Water absorption 28 days JIS 6767: 0.03 mg/cm

2-Compression strength at 25% compression ISO 844: 70 kPa

- Compression creep (thickness loss) at 23

oC, 20 kPa load

- 8 hours: 0.1%

- 408 hours: 0.6%

- 10,000 hours: 2.0%

Prices:

Quiet Step Underlay - 20 m2 roll (20 m x 1 m x 2 mm): $9.00 + GST per m2 or $180.00 + GST per roll.

Quiet Step Underlay - 50 m2 roll (50 m x 1 m x 2 mm): $6.50 + GST per m2 or $325.00 + GST per roll.

Quiet Step Combi-Lay - 20 m

2 (20 m x

1 m x 2 mm): $10.00 + GST per m

2 or $200.00 + GST per roll.

Quiet Step Combi-Lay

- 50 m2 (50 m x

1 m x 2 mm): $7.40 + GST per m

2 or $37

0.00 + GST per roll.Underlay purchases are full rolls only.

Info Links

Premium Quiet Step Acoustic UnderlayPremium Quiet Step Underlay Test Report Vibramat Acoustic underlay

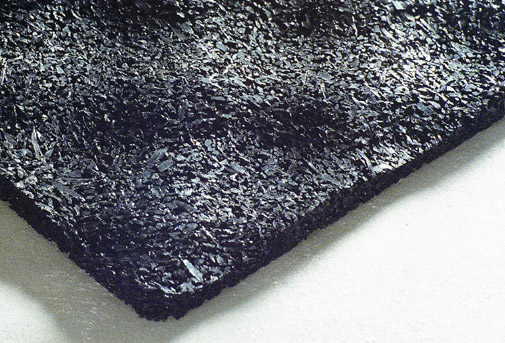

Vibramat is specifically designed to be used under tiles and timber floors in high rise buildings for the purpose of reducing footfall and impact noise. The way a resilient underlay like Vibramat works, is by absorbing (and to a certain extent reflecting) as much impact noise as possible before allowing the energy to reach the structure of the building. This is what acoustic engineers commonly refer to as 'impact isolation'.

The raw materials used in making Vibramat come from either recycling old tyres, collecting waste rubber in the form of off-cuts from shoe factories etc, or from cork waste collected from the bottling industries.

Distinct from other manufacturers of acoustic underlay, Vibramat comes in flat sheets measuring precisely 1.1m x 1.1m (1.21m2 per sheet) for easier installation compared to rolled underlay. Stock standard thickness is 5 mm in the 100% rubber type.

Benefits:

- High performance at low cost

- Effective solution in meeting or exceeding the BCA acoustic requirements

- Environmentally responsible by using recycled and waste raw materials

- Acoustic test report is available on request.

Price:

5 mm $15.40 + GST per m2 or $18.60 + GST per sheet 1.1 m x 1.1.m

Vibrapad

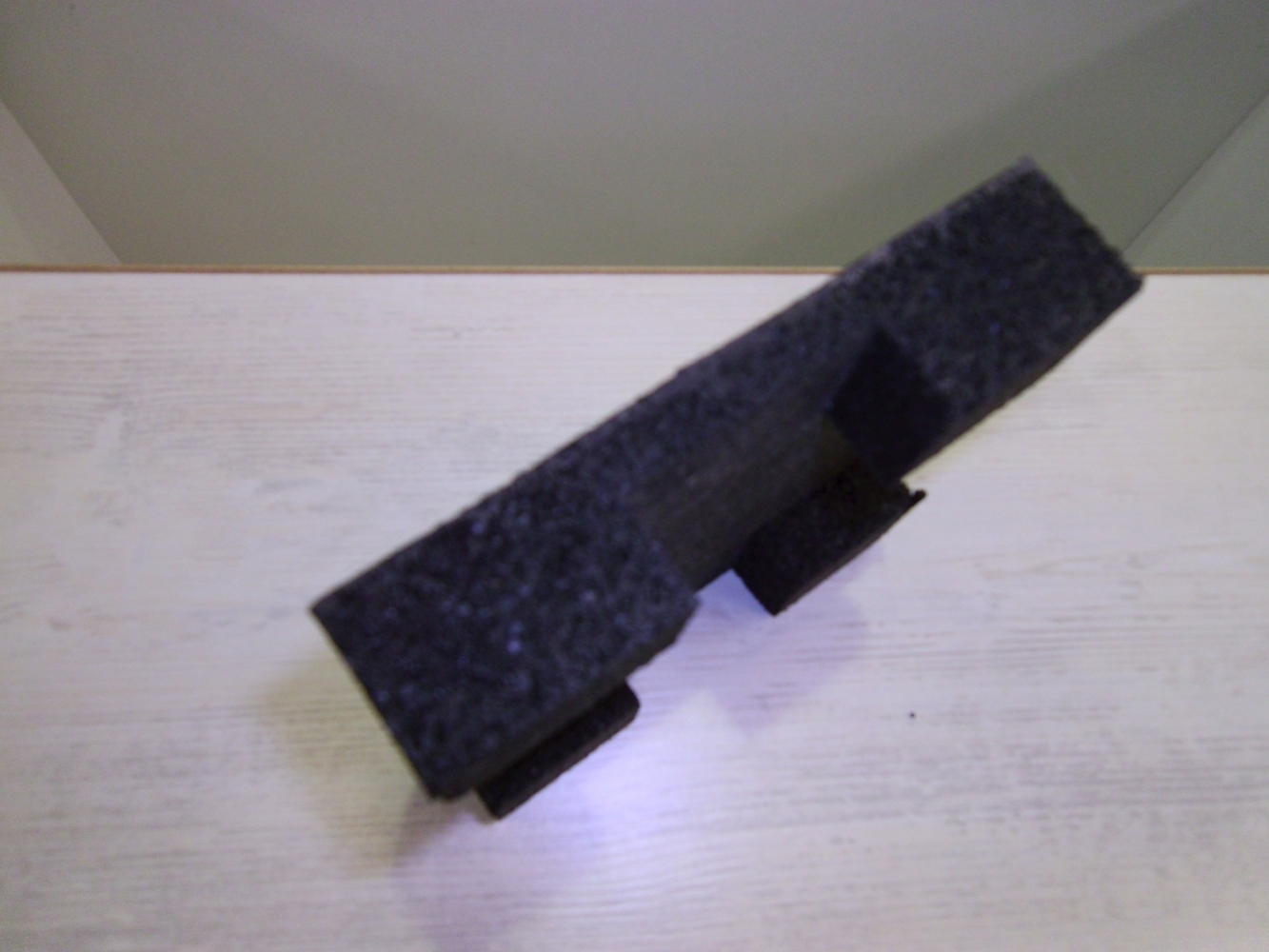

Vibrapad is a unique resilient rubber pad system which provides for higher level of floor impact isolation compared to a conventional underlay system. Vibrapad works by mainly absorbing as much impact noise as possible before allowing the energy to reach the structure of the building.

The recommended spacing between each Vibrapad is 450 mm centre to centre, and is designed for standard hardwood battens to fit snugly. Battens are the way to fix a structural timber flooring over concrete. The biggest advantage of having timber battens is that it can be spot planed and leveled. In this way the traditional tongue and groove timber floorboards could be nailed onto the hardwood battens. The performance of Vibramat system could be enhanced by using polyester or glass fibre insulation between the hardwood battens.

Vibrapad comes in size 120 mm x 120 mm and thickness 10 mm, 100 pieces in a box.

Price: $445 + GST per box.

Vibrapad is manufactured using very high quality granulated recycle rubber for precise dimensional accuracy and uniformity.

Benefits:

- Higher performance at even lower cost

- System that will more than exceed the BCA acoustic requirements

- Environmentally responsible by using recycle and waste materials

- Easy and economical way to level a floor by shaving the timber battens

Planet Flooring can assist you with the report to Strata management regarding acoustic underlay required under floating floors.

Info Links

RHEXE Silent Underlay

1. Description:

RHEXE Silent Underlay can be used to bond solid timber and floating floors in residential and commercial buildings. The underlay is a high quality polyethylene foam mat with symmetrically distributed cut outs. It provides an excellent sound damping effect improving the acoustic performance in rooms.

Colour: Black- Thickness: 3 mm

- Density: 32 kg / m3

- Packaging: 100 m2 rolls

- Width of the roll: 1.10 m

- The underlay can be walked during installation

- Floors can be walked on 24 hours after the installation / gluing without heavy or concentrated loads. The - floors are fully serviceable after 48 hours

- Easy to install using RHEXE FLEX 500 high performance single component flooring adhesive,moisture curing polyurethane adhesive in 600 mL sausage and application gun

- Cost effective.

Price: $7.40 + GST per m2 or $740 + GST for Roll of 100 m2.

2. Surface Preparation:

- All surfaces shall be dry, sound and smooth, free of wax, curing compounds, grease, paint, old adhesives, dust and dirt

- New concrete surfaces must be completely cured. Ensure the moisture content of the concrete is below 5%. To assess sub-floor moisture level prior to adhesive application use an appropriate moisture reading apparatus. If the moisture content is above the acceptable limits Holdfast Uroseal 2 part water based epoxy moisture barrier should be applied.

- Uroseal is specifically developed to provide an effective barrier against moisture and moisture seepage from sub-floors that contain excessive moisture

- No preparation is required on dry, dense and wearable substrates

3. Application

- Position RHEXE Silent underlay mats close to each other without overlapping

- Apply RHEXE FLEX 500 adhesive with the application gun into all cut outs in the mat. The gun nozzle must be held vertical to the substrate. Important note: Adhesive must not be placed onto the mat between the cut outs

- Position the floor boards and firmly press them into the adhesive until they lay tight on the RHEXE Silent Underlay. The floor boards can then be joined together with a hammer and according the manufacturer's instructions.

4. Important Notification

This technical information provides only assistance for purchasers. It is of a general nature based on our product knowledge, experience and test we believe to be reliable. However, no guarantee of accuracy can be given due to the differences in materials, substrates, actual field conditions and methods at the working place.

We recommend that purchasers carry out their own tests in order to determine the suitability of the adhesive product for particular purposes.

Info Links

Rhexe Silent Underlay Technical Information and Acoustic Test Report